Execution of a sequence

There are two cases to differentiate:

Using an CAMAG® HPTLC PRO SYSTEM without any CAMAG® HPTLC PRO Module PLATE STORAGE

Click on the  button of the sequence to execute it for this HPTLC PRO SYSTEM.

button of the sequence to execute it for this HPTLC PRO SYSTEM.

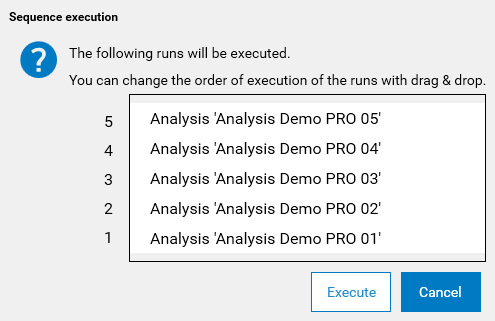

A popup will list the runs (with analysis name) as a stack (the first one is the lowest). It is possible to re-order the runs inside this sequence by dragging a run to another place in the list. Validate it.

Using an HPTLC PRO SYSTEM with a CAMAG® HPTLC PRO Module PLATE STORAGE

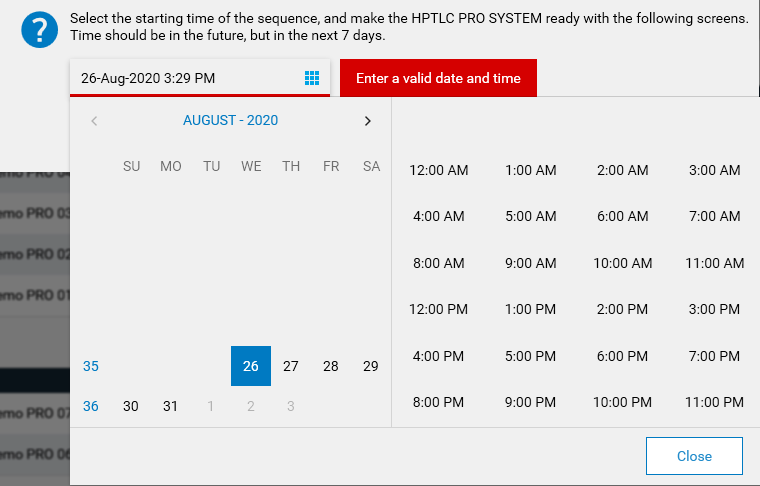

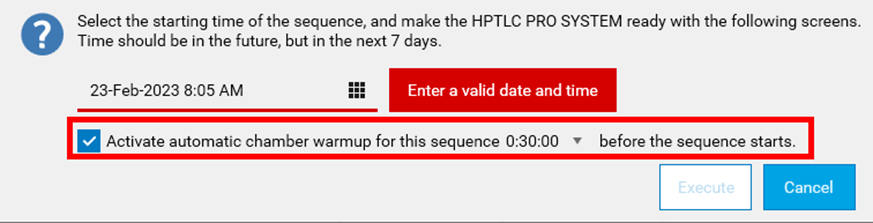

It is possible to differ the execution by clicking on the  button of the sequence to first select a start time.

button of the sequence to first select a start time.

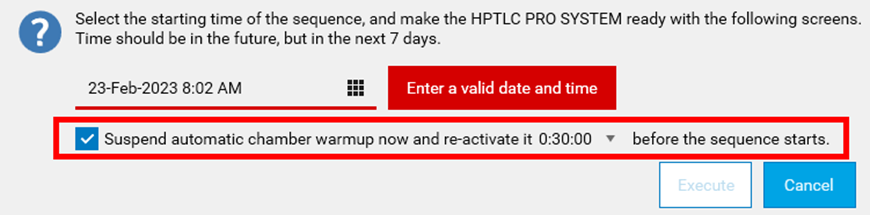

When using an HPTLC PRO DEVELOPMENT Module, it is also possible to manage the chamber temperature regulation:

If the automatic chamber temperature regulation is activated, it is possible to suspend it and reactivate it before the sequence starts. This avoids unnecessary regulation, for example during a night or a weekend.

If the automatic chamber temperature regulation is deactivated, it is possible to activate it temporarily before and during the sequence. This allows to reduce regulation time when the development steps start.

Note

The HPTLC PRO SYSTEM must already be ready with all consumables and carriers, exactly like if the sequence is executed immediately.

Otherwise click on the  button to start the sequence execution immediately in the HPTLC PRO SYSTEM.

button to start the sequence execution immediately in the HPTLC PRO SYSTEM.

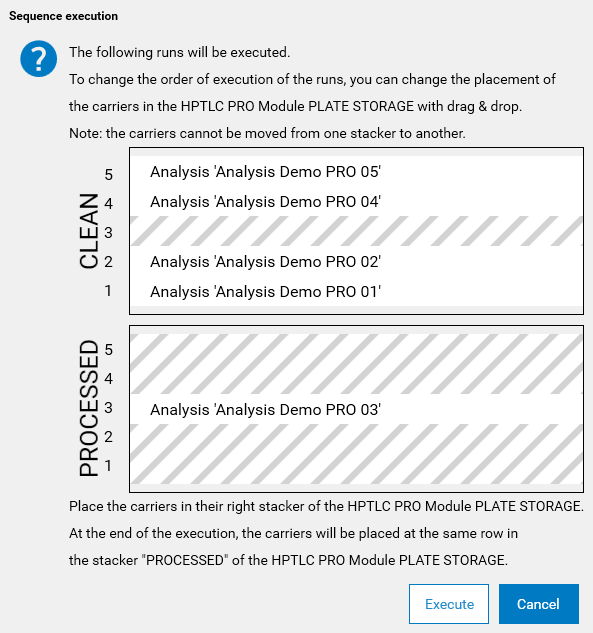

A popup will show how to place the carriers in the stackers of the module PLATE STORAGE:

Some carriers may have to be placed in the processed stacker because the plate was marked as not clean when the run was added to the sequence (see HPTLC PRO)

The row number in the module PLATE STORAGE determines the order of execution of the runs.

The order can be changed, but a carrier cannot be moved from a stacker to another.

Moving a carrier in a stacker may affect the carrier places of the other one.

When the Execute button is hit, a check is first made to ensure that the configuration matches with the HPTLC PRO Module PLATE STORAGE state. If not, the errors are displayed and the carriers must be placed as expected in the stackers. When changes are made in the module and the door is closed, the software automatically checks if its state matches with the configuration. The popup is then updated to indicate the new status.

After validation, the following steps are common to both cases:

The Needed consumables for execution popup and then rack position popup (if needed) will be displayed. See Consumables check. Validate when all consumables are correctly set.

The first run will then start (if no start time is set), and after, as soon as possible, the second one, etc.

Note

The entire sequence is executed and it is not possible to execute only some runs of a sequence. The user will have to abort a run if its execution is not desired for this sequence.