Consumables validation

As HPTLC PRO is geared towards automation, the consumables of the HPTLC PRO Modules, such as the rack of the module APPLICATION or the solvents of the module DEVELOPMENT, must be defined and managed by visionCATS. This allows the software to check if all consumables are present prior to the execution of a sequence.

Consider the HPTLC PRO Module. In the Properties tab, visionCATS users can define the current state of the consumables, for example to define the solvent name of the 1st bottle of the module DEVELOPMENT.

Then, consider an analysis. The Chromatography tab defines as usual the:

The vials in the Track Assignment table,

The solvent names in Instrument step parameters.

Moreover, the vials are assigned to a rack when the run is added to a sequence (see HPTLC PRO). So the rack of a sequence is configured during the add of the runs to the latter.

This defines what the run will do, not how. In other words, the analysis parameters do not depend on the HPTLC PRO Modules which will execute the steps. The matching can only be done when the sequence is started on a connected CAMAG® HPTLC PRO SYSTEM. visionCATS can then associate each analysis step with the corresponding HPTLC PRO Module to establish how the runs can be performed.

For example, if a module DEVELOPMENT step requires the Dichloromethane mobile phase, visionCATS searches through the bottles of the module DEVELOPMENT if Dichloromethane is present:

If found, then Dichloromethane is associated to the corresponding bottle

If not found, then the consumables popup is shown to the user to help him fulfill the requirements.

This way, visionCATS checks all the consumables before the run is started:

CAMAG® HPTLC PRO Module APPLICATION:

Check Solvent 1 name of the step <-> Bottle 1 content of the module

Check Solvent 2 name of the step <-> Bottle 2 content of the module

CAMAG® HPTLC PRO Module DEVELOPMENT:

Check if Preconditioning solvent of the step corresponds to one of the bottles of the module (Bottle 1 content, Bottle 2 content, Bottle 3 content)

Same for Development solvent of the step

Same for Conditioning solution of the step

Check if Activation salt solution of the step <-> Activation bottle content of the module

CAMAG® HPTLC PRO Module DERIVATIZATION:

Check if Reagent of the step corresponds to one of the bottle of the module (Bottle 1 content, Bottle 2 content)

Check if Cleaning solvent of the step <-> Cleaning bottle content of the module

Check if Nozzle type of the step is detected in one of the slots of the module, and if the corresponding nozzle is washed

Check if the derivatization chamber is cleaned and if the cleaning bottle is not empty

Check if the frame and the derivatization hood (left and right) are correctly placed

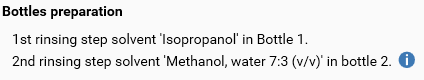

Consumables check

In Chromatography tab of the analysis

Before adding a run to a sequence, an information is displayed in the Instruction display if the module does not have the needed consumables. At this stage, the potential consumable conflict is only informational because the sequence may be executed later, after a change of consumables.

In details view of HPTLC PRO SYSTEM

The actual check is performed when the execution of the corresponding sequence is started. If something does not match, a Needed actions for execution popup is displayed.

The view is made of three parts:

Step selection: a table view displays every step of each run (if the sequence contains more than one run). Steps are grouped by HPTLC PRO Module and make the columns of the table. Each run is displayed as a row in the table, named by the analysis name. Only one step of one run can be selected at one time, and it will change the view below. The steps with issues are marked as Failed, the others as Passed.

Needed consumables: All consumables needed for the above selected step will be displayed here. The matching errors are displayed in red.

Note

The needed consumables are read-only as they are defined in the analysis.

Current consumables of the HPTLC PRO Module: here, the declaration of HPTLC PRO Module’s consumables can be modified. It should match the needed consumables above.

Important

Current consumables (and instrument properties) is only declarative. visionCATS is not able to detect the content or volumes of the bottle. The user is responsible of first changing the consumables on the HPTLC PRO Module, and then updating the declaration in visionCATS.

Note

In case of several bottles having the same content, only the first of these bottles will be used. A warning would be displayed as reminder.

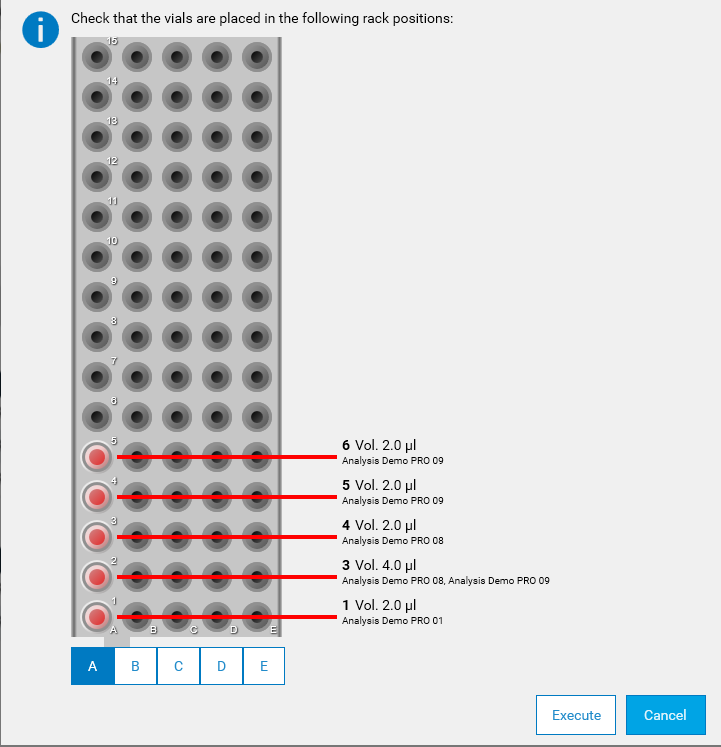

Vial position in HPTLC PRO Module APPLICATION rack

In Chromatography tab of analysis

With a HPTLC PRO Module APPLICATION, when adding a run to a sequence (see HPTLC PRO), the rack positions are automatically assigned to vials. The rack is filled from column A to E and from row 1 to 15 (so A1, A2… A15, B1, B2… E15).

If some vials are reused from one run to another, the vial positions are reused and the volumes are adjusted.

If a run is aborted, the vials are removed from the rack, but the other vials positions remain unchanged. So it is possible to have some “holes” in a rack, and these holes will be filled in priority if a run is then added to the sequence. Select one of the A to E columns to see which vial must be placed in which position before the execution.

Note

The vials of the current run are highlighted to show where they are placed.

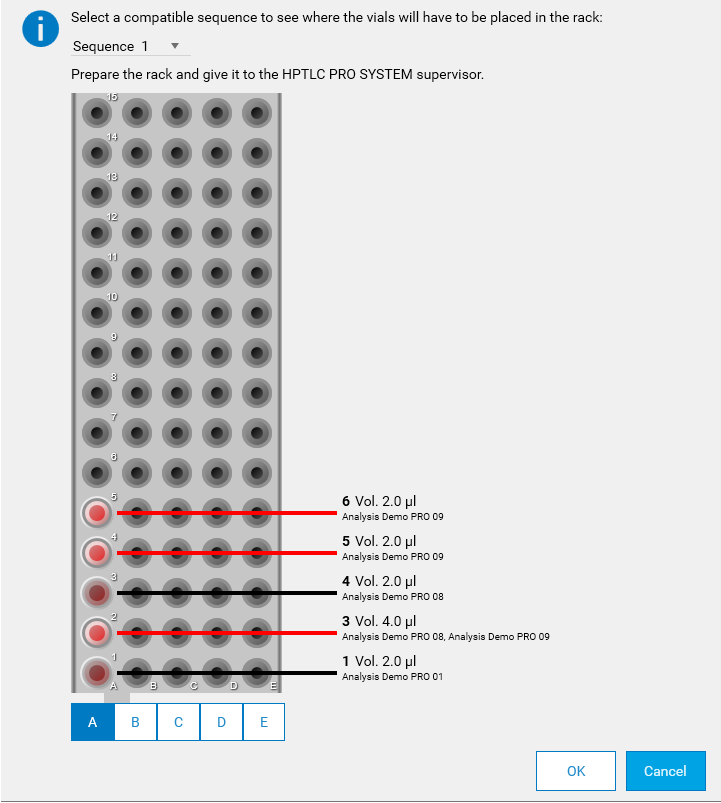

In details view of HPTLC PRO SYSTEM

After correcting all the consumables issues, and validating the Needed consumables for execution popup, another popup displays how to the rack must have been filled. Select one of the A to E columns to see which vial must have been placed in which position before the execution.